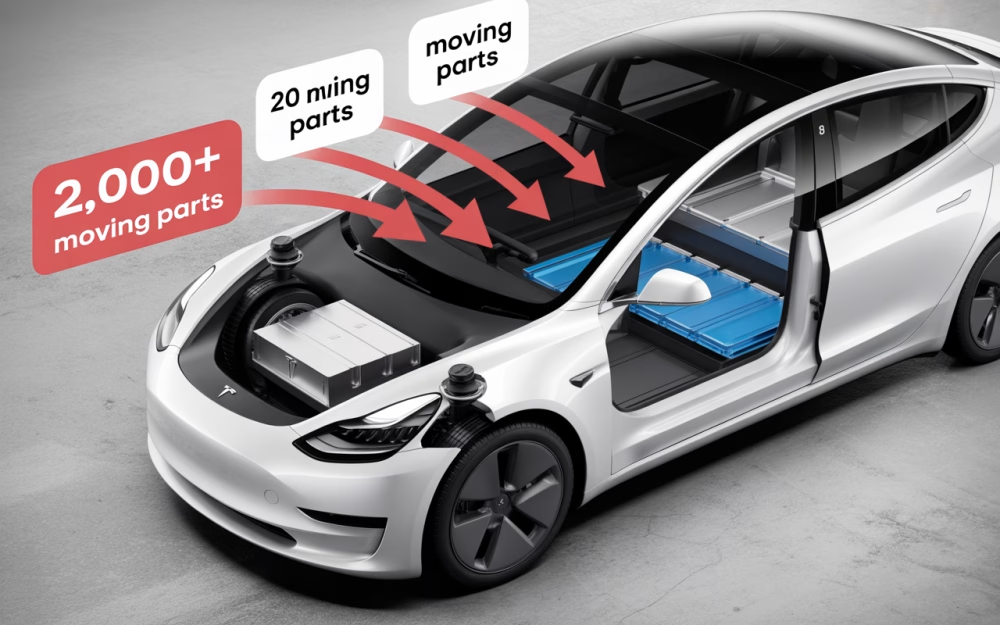

Have you ever wondered why Tesla owners report going 100,000 miles without major maintenance while traditional car owners are scheduling oil changes every few months? The answer lies in a stunning engineering reality: a Tesla contains approximately 20-25 moving parts in its drivetrain, compared to over 2,000 in a conventional gasoline vehicle. This isn’t just a minor improvement—it’s a fundamental reimagining of automotive design that affects everything from reliability to your wallet.

If you’ve ever been curious about what makes electric vehicles so mechanically different from traditional cars, you’re in the right place. The question “how many moving parts are in a Tesla?” reveals a fascinating story of innovation, simplification, and engineering brilliance.

In this comprehensive guide, you’ll discover the exact breakdown of Tesla’s mechanical components, understand why fewer moving parts translates to lower maintenance costs and improved reliability, and learn how Tesla’s minimalist approach extends from the electric motor to the HVAC system.

Whether you’re considering purchasing a Tesla, fascinated by automotive engineering, or simply want to understand what makes these vehicles tick (or rather, not tick with hundreds of moving components), this deep dive will transform how you think about modern transportation.

Table of Contents

Understanding Tesla’s Innovative Mechanical Design

When Elon Musk and his team set out to revolutionize the automotive industry with Tesla, they didn’t just aim to replace gasoline with electricity—they fundamentally reimagined how a car should be built. Traditional combustion engine vehicles have evolved over a century, accumulating complexity with each generation. These conventional vehicles typically contain around 2,000+ moving parts in their drivetrains alone, creating countless potential failure points and maintenance needs.

Tesla’s approach represents a radical departure from this paradigm. By embracing electric propulsion, Tesla vehicles operate on a philosophy of mechanical minimalism—achieving superior performance not by adding complexity but by strategically eliminating it. This design philosophy touches every aspect of Tesla’s vehicles, from powertrain to climate control systems.

The stark contrast becomes apparent when examining the drivetrain. While a conventional vehicle requires an intricate orchestra of pistons, valves, crankshafts, and gears working in precise harmony, Tesla’s electric powertrain achieves the same function—converting energy into motion—with dramatically fewer components. This simplification doesn’t compromise performance; rather, it enhances it, delivering instant torque and smoother acceleration than most internal combustion vehicles.

Tesla’s mechanical simplicity extends beyond just the powertrain. From the regenerative braking system that reduces wear on physical brake components to the streamlined HVAC systems, Tesla has reimagined virtually every mechanical system in the automobile. This approach yields benefits in reliability, maintenance requirements, manufacturing efficiency, and ultimately, the ownership experience.

The result is a vehicle that doesn’t just drive differently but is fundamentally different in its mechanical composition—a distinction that becomes increasingly important as we examine exactly how many moving parts are in a Tesla compared to conventional vehicles.

How Many Moving Parts Are in a Tesla?

A Tesla electric vehicle contains approximately 20-25 moving parts in its drivetrain, compared to the 200+ moving parts found in a conventional internal combustion engine vehicle. This dramatic reduction represents one of the most significant engineering advantages of electric vehicles.

The exact count varies slightly depending on the specific Tesla model, but the difference remains striking. A traditional gas-powered car requires pistons, valves, connecting rods, crankshafts, camshafts, timing belts or chains, fuel pumps, and numerous other components that continuously move during operation. Each of these parts introduces potential failure points and maintenance requirements.

Breaking down Tesla’s moving parts by major components:

- Electric motor: 2-3 moving parts (rotor, bearings)

- Single-speed transmission: 5-10 moving parts (compared to 100+ in a conventional transmission)

- Cooling system: 3-5 moving parts (pumps, fans)

- Braking system: 10-15 moving parts (similar to conventional vehicles but with less wear due to regenerative braking)

The dramatic reduction in moving parts directly translates to improved reliability, reduced maintenance costs, and extended vehicle lifespan. With fewer mechanical components that can wear out, break, or require lubrication, Tesla vehicles can often go much longer between service appointments than their gasoline-powered counterparts.

This simplicity is one of Tesla’s greatest engineering achievements—creating high-performance vehicles that deliver exceptional power and range while simultaneously reducing mechanical complexity to levels previously unimaginable in the automotive industry.

The Electric Motor: Tesla’s Mechanical Heart

At the core of Tesla’s revolutionary design lies its electric motor—an engineering marvel that dramatically reduces mechanical complexity compared to traditional internal combustion engines. While a conventional gas engine contains approximately 200+ moving parts (pistons, valves, crankshafts, connecting rods, etc.), a Tesla’s electric motor contains just one primary moving component: the rotor.

This single rotating element spins within a stationary stator, creating motion through electromagnetic principles rather than controlled explosions and mechanical linkages. The elegant simplicity of this design eliminates countless potential failure points while delivering superior performance characteristics.

Tesla employs two primary types of electric motors across its vehicle lineup:

Induction Motors: Used in earlier Model S and Model X vehicles, these motors use electromagnetic induction to create rotation. The rotor contains no permanent magnets but instead relies on induced current to create a magnetic field. While slightly less efficient than permanent magnet designs, induction motors excel at high-power applications and have exceptional durability due to their robust construction.

Permanent Magnet Synchronous Motors (PMSM): Found in the Model 3, Model Y, and newer versions of the Model S and X, these motors incorporate permanent magnets in the rotor design. This configuration offers higher efficiency, particularly at lower speeds and partial loads, which translates to better range for everyday driving conditions.

Most Tesla vehicles actually contain multiple motors—either dual-motor all-wheel drive or tri-motor configurations in performance models. Even with these additional motors, the total moving part count remains remarkably low compared to combustion vehicles. Each additional motor adds just one more primary moving component to the vehicle’s drivetrain.

The radical simplification of the drivetrain architecture doesn’t come at the expense of performance. In fact, Tesla’s motors deliver instant torque, seamless acceleration, and power-to-weight ratios that conventional engines can rarely match. This perfect marriage of mechanical simplicity and performance capability represents one of Tesla’s most significant innovations in automotive design.

Tesla’s Battery System: Minimal Movement, Maximum Power

Tesla’s battery system represents one of the most remarkable engineering achievements in modern vehicle design, particularly when examining how many moving parts are in a Tesla. Unlike traditional vehicles with fuel pumps, fuel lines, injectors, and other constantly moving components, Tesla’s battery system operates with astonishing mechanical simplicity.

The battery pack itself—typically containing thousands of individual lithium-ion cells—has virtually zero moving parts during normal operation. These cells are stationary, arranged in modules and secured within a rigid protective structure beneath the vehicle’s floor. This placement creates a low center of gravity while eliminating the need for mechanical fuel delivery systems entirely.

The only “movement” within the battery system occurs at the microscopic level, where lithium ions shuttle between the anode and cathode during charging and discharging cycles. This electrochemical process replaces dozens of moving components found in traditional combustion engines, where fuel must be physically pumped, injected, and combusted.

Tesla’s battery cooling system does incorporate some moving elements, though far fewer than conventional vehicles. The thermal management system uses a liquid coolant that circulates through channels surrounding the battery cells, maintaining optimal operating temperatures. This circulation requires a pump—one of the few true moving components in the entire battery system. Some models employ a simple valve system to direct coolant flow based on temperature needs, adding just a handful of additional moving parts.

The battery management system (BMS) monitors and controls the battery’s performance without requiring mechanical action. Instead of physical regulators, the BMS uses electronic sensors and controllers to maintain battery health, representing another area where Tesla has replaced moving components with solid-state electronics.

When comparing the battery system to a traditional fuel system, the contrast is stark. A conventional vehicle might have fuel pumps, pressure regulators, injectors, float mechanisms, and various valves—easily exceeding 20-30 moving parts just in the fuel delivery system. Tesla’s battery system accomplishes the same fundamental goal—energy storage and delivery—with perhaps 2-3 moving parts in the cooling system, demonstrating how Tesla’s engineering philosophy dramatically reduces mechanical complexity.

Tesla’s Single-Speed Transmission

Unlike conventional internal combustion engine vehicles that require complex multi-gear transmissions, Tesla’s electric vehicles operate with an elegantly simple single-speed transmission system. This fundamental difference represents one of the most significant reductions in moving parts across the entire vehicle.

A traditional automatic transmission in a gasoline-powered car contains approximately 800-1,000 moving parts—including planetary gear sets, clutch packs, valve bodies, torque converters, and intricate hydraulic systems. Manual transmissions are somewhat simpler but still contain hundreds of precision components that must work in perfect harmony.

Tesla’s single-speed transmission, by contrast, contains roughly 20 moving parts. The system consists primarily of a simple reduction gear that connects the electric motor to the drive wheels. This single-gear design is possible because electric motors deliver consistent torque across a much wider RPM range than internal combustion engines, eliminating the need for multiple gears to maintain optimal power delivery.

The simplicity of Tesla’s transmission system offers several advantages beyond just part count reduction. With fewer moving components, there’s less friction, reduced weight, improved reliability, and virtually no maintenance requirements. Tesla owners never need to worry about transmission fluid changes, clutch replacements, or the complex repairs that plague conventional transmissions.

This minimalist approach to power transmission is a perfect example of how Tesla’s engineering philosophy—removing unnecessary complexity wherever possible—results in a vehicle with dramatically fewer moving parts while improving performance and reliability.

Regenerative Braking: Fewer Brake Components

Tesla’s regenerative braking system represents one of the most significant reductions in moving parts compared to traditional vehicles. In conventional cars, the braking system contains numerous mechanical components including brake pads, rotors, calipers, pistons, and hydraulic lines—each with multiple moving parts that experience wear over time.

Tesla vehicles, however, leverage their electric motors as generators during deceleration. When a driver lifts off the accelerator pedal, the electric motor reverses its operation, creating resistance that slows the vehicle while simultaneously converting kinetic energy back into electrical energy to recharge the battery. This ingenious system accomplishes two goals simultaneously: extending battery range and dramatically reducing wear on the mechanical braking system.

While Teslas still maintain traditional friction brakes for emergency stopping and situations where regenerative braking isn’t sufficient, these components experience significantly less wear. The reduction in brake usage is so substantial that many Tesla owners report their brake pads lasting well beyond 100,000 miles—sometimes even the lifetime of the vehicle. This contrasts sharply with conventional vehicles that typically require brake pad replacement every 30,000-50,000 miles.

In terms of moving parts, a Tesla’s braking system contains approximately 50% fewer components than traditional hydraulic braking systems. The regenerative system primarily uses the existing motor and power electronics rather than dedicated mechanical components. The reduced friction brake usage means fewer moving parts in constant operation, less hydraulic fluid circulation, and minimal caliper movement during normal driving conditions.

This reduction in mechanical complexity not only improves reliability but also eliminates common brake-related issues like squeaking, uneven wear, and brake dust accumulation that plague conventional vehicles. The elegant simplicity of regenerative braking exemplifies Tesla’s overall philosophy of reducing mechanical complexity wherever possible.

Tesla’s Minimalist Suspension System

Tesla’s suspension system represents another area where the company has streamlined mechanical complexity while maintaining exceptional performance. Unlike traditional vehicles with numerous interconnected components, Tesla’s suspension design embraces minimalism without sacrificing functionality.

The standard suspension system in Tesla vehicles contains approximately 20-25 moving parts per wheel assembly, significantly fewer than the 30-40 parts found in conventional vehicles. This reduction is achieved through intelligent integration and the elimination of redundant components.

Tesla’s suspension architecture varies slightly across its model lineup, but generally includes:

- Adaptive dampers with fewer internal valves

- Simplified control arms and linkages

- Integrated hub assemblies

- Reduced bushing count

- Streamlined anti-roll bar connections

The company’s Smart Air Suspension system, available on higher-end models, adds complexity but with remarkable efficiency. This system incorporates:

- Air springs that replace traditional coil springs

- Electronic height adjustment actuators

- Pressure sensors and electronic controllers

- Self-leveling capabilities requiring minimal moving parts

What makes Tesla’s air suspension particularly innovative is how it achieves adaptability with fewer mechanical elements. The system can adjust ride height automatically based on GPS location (remembering challenging driveways or speed bumps) and driving conditions, all while using simplified pneumatic components that have fewer failure points than traditional adaptive suspensions.

By reducing the moving parts count in the suspension system, Tesla vehicles benefit from decreased unsprung weight, which improves handling responsiveness and ride comfort. The simplified design also contributes to the vehicle’s overall reliability and reduced maintenance requirements, as fewer components mean fewer potential points of mechanical failure over time.

The Absence of Traditional Engine Components

When you pop the hood of a Tesla, the first thing you’ll notice is what’s missing—the complex array of components that make up an internal combustion engine (ICE). This absence represents one of the most significant reductions in moving parts in automotive history.

A traditional ICE vehicle contains hundreds of components working in precise synchronization:

- Pistons: Typically 4, 6, or 8 pistons moving up and down thousands of times per minute

- Valves: Each cylinder requires multiple intake and exhaust valves (often 16-32 total)

- Camshafts: Rotating shafts with precision-ground lobes to control valve timing

- Timing belts or chains: Connect the crankshaft to the camshafts

- Fuel injectors: One per cylinder, with precision moving parts

- Crankshaft: Converts the pistons’ linear motion into rotation

- Connecting rods: Link pistons to the crankshaft

- Oil pump: Circulates lubricant throughout the engine

- Water pump: Circulates coolant through the engine block

- Alternator: Generates electricity with internal moving components

- Fuel pump: Pressurizes fuel for delivery to injectors

- Throttle body: Controls airflow with moving butterfly valve

- Exhaust gas recirculation valve: Reduces emissions

This traditional setup contains approximately 200+ moving parts in the engine alone. Tesla’s electric powertrain eliminates all of these components, replacing them with an electric motor that has just one primary moving part—the rotor.

The quantifiable reduction is staggering: Tesla has eliminated roughly 90% of the moving parts found in a traditional vehicle’s powertrain. This massive simplification not only improves reliability but also reduces maintenance requirements and potential failure points dramatically.

HVAC and Thermal Management Systems

Tesla’s approach to heating, ventilation, and air conditioning (HVAC) represents another area where the company has dramatically reduced moving parts compared to conventional vehicles. Traditional automotive HVAC systems typically rely on multiple mechanical components including compressors, blower motors, actuators for directing airflow, and various valves—all with their own moving parts that can potentially fail.

Tesla’s more recent models feature an innovative heat pump design that significantly reduces mechanical complexity. The Model Y was the first to introduce this system, which was later implemented in the refreshed Model 3, Model S, and Model X. This heat pump operates on similar principles to a home refrigerator but with greater efficiency and fewer mechanical elements.

The heat pump’s design is remarkably elegant—it can extract heat from the ambient air even in cold conditions and transfer it to the cabin. During hot weather, it reverses this process to cool the interior. The system requires far fewer moving parts than traditional automotive heating systems that rely on engine heat (which electric vehicles don’t produce) or resistive heating elements (which consume significant battery power).

One of the most impressive aspects of Tesla’s thermal management system is its integration with the battery cooling circuit. Rather than having separate systems for cabin climate control and battery temperature management—each with their own pumps, valves, and actuators—Tesla’s design uses an interconnected “octovalve” system that manages thermal distribution throughout the vehicle with minimal moving components.

This octovalve, despite its complex function, actually represents a reduction in moving parts compared to traditional systems. It replaces multiple separate valves and actuators with a single component that directs refrigerant and coolant flow throughout the vehicle’s thermal systems.

The air distribution system inside the cabin also demonstrates Tesla’s minimalist approach. While traditional cars might use multiple mechanical flaps and actuators to direct air to different vents, Tesla employs a more streamlined design with fewer mechanical elements. The company’s focus on software control rather than mechanical complexity allows for sophisticated climate management without the associated maintenance concerns of numerous moving parts.

Moving Parts in Tesla’s Autopilot Hardware

Tesla’s Autopilot system represents one of the most advanced driver assistance technologies available today, yet it maintains remarkable mechanical simplicity compared to other automotive systems. While the system is predominantly electronic and computational, there are still several crucial moving parts that enable its functionality.

The exterior camera system forms the foundation of Tesla’s Autopilot vision. Each vehicle is equipped with eight cameras positioned strategically around the car. These cameras contain small but critical mechanical components, including focus mechanisms and protective lens covers that automatically adjust in various weather conditions. Some models feature tiny wiper systems for certain cameras to maintain visibility during rain or snow.

Radar sensors (in pre-2021 models) included mechanical elements for precise positioning and adjustment. These components needed to maintain perfect alignment for accurate data collection, requiring calibrated mounting hardware with minimal but essential moving parts. While Tesla has moved away from radar in newer vehicles, these components were integral to earlier Autopilot systems.

Ultrasonic sensors around the vehicle perimeter contain piezoelectric elements that physically vibrate to generate sound waves. Though microscopic in movement, these vibrations are technically moving parts essential to the sensor’s operation. These tiny movements allow the vehicle to detect nearby objects with remarkable precision.

Perhaps the most significant moving parts in the Autopilot system are the actuators that physically control the vehicle. These include:

- Steering rack actuators that translate electronic commands into physical steering movements

- Brake actuators that apply precise pressure to the braking system

- Acceleration actuators that control power delivery to the motors

The internal computing hardware, while not visible to users, contains cooling fans and heat management systems with moving parts. These components are crucial for maintaining optimal operating temperatures for the neural network processors that power Autopilot functionality.

Interestingly, Tesla has continuously worked to reduce moving parts even within the Autopilot system. The shift away from radar to a pure vision-based approach eliminated several mechanical components, further simplifying the system while improving its capabilities. This commitment to mechanical simplicity while enhancing functionality demonstrates Tesla’s innovative approach to automotive design.

Interior Moving Components: Simplicity by Design

Tesla’s commitment to mechanical minimalism extends beyond the powertrain and into the cabin, where interior moving parts have been carefully engineered to balance functionality, durability, and design elegance. Unlike traditional vehicles where buttons, knobs, and levers dominate the dashboard, Tesla has embraced a philosophy of “less is more” for its interior mechanical elements.

The door mechanisms in Tesla vehicles represent this simplified approach perfectly. The Model 3 and Model Y feature flush door handles that pivot out electronically when approached with the key fob or when touched. Inside, the emergency door release mechanisms are designed with fewer moving components than conventional systems, reducing potential failure points while maintaining safety standards.

Window regulators in Teslas utilize modern electric motors with fewer moving parts than older cable-driven systems. This not only improves reliability but also enables the precise control needed for features like the “auto-up” function with pinch protection. The simplified design allows for smoother operation and reduced noise during window movement.

Seat adjustment systems in Tesla vehicles offer extensive customization through electric motors rather than mechanical levers. The Model S and Model X provide up to 12-way power adjustable seats with fewer mechanical linkages than traditional systems. These seats store position preferences in driver profiles, requiring sophisticated electronics but significantly fewer moving mechanical components than seats with manual adjustments.

The steering column adjustment mechanism has also been simplified, using electric motors instead of the typical mechanical levers and locking mechanisms. This reduces complexity while providing the same functionality and improved ease of use.

Perhaps most notably, Tesla has dramatically reduced dashboard controls by centralizing functions in the touchscreen interface. This eliminates dozens of mechanical buttons, switches, knobs, and sliders found in conventional vehicles. While this approach has sparked debate about usability, it undeniably reduces mechanical complexity and potential failure points.

Even small details reflect this philosophy—the glovebox in newer Tesla models opens via touchscreen command rather than a mechanical latch, and the sunglass holders use magnetic closures instead of spring-loaded mechanisms. The center console in the refreshed Model S and Model X features motorized doors with fewer mechanical components than traditional hinged designs.

This comprehensive approach to interior simplicity contributes significantly to the overall reduction in moving parts throughout Tesla vehicles, enhancing reliability while creating the clean, minimalist aesthetic that has become a hallmark of the brand.

Maintenance Implications of Fewer Moving Parts

One of the most significant advantages of Tesla’s streamlined mechanical design is the dramatic reduction in maintenance requirements. With estimates suggesting that a Tesla contains only 20-25 moving parts in its drivetrain compared to approximately 200+ in a conventional internal combustion engine vehicle, the maintenance implications are profound.

The fewer moving parts in a Tesla directly translates to enhanced reliability. Traditional vehicles contain numerous components that experience constant friction, heat, and mechanical stress—pistons, valves, crankshafts, connecting rods, and transmission gears all represent potential failure points. In contrast, Tesla’s electric motors primarily consist of a rotor and stator, with minimal mechanical wear during operation.

This simplified mechanical architecture transforms the maintenance schedule for Tesla owners. Gone are the regular oil changes, transmission fluid replacements, timing belt services, and spark plug replacements that conventional vehicle owners must schedule. Tesla’s official maintenance recommendations reflect this simplicity:

- Cabin air filter replacement: Every 2-3 years

- Brake fluid test: Every 2 years

- Air conditioning service: Every 4-6 years

- Tire rotation and wheel alignment checks: Every 10,000-12,000 miles

The longevity of Tesla components also benefits from this reduced mechanical complexity. Electric motors typically last significantly longer than internal combustion engines, with many designed to function for 1,000,000+ miles before requiring major service. The battery pack, while not technically containing “moving parts,” represents the most significant maintenance consideration for Tesla owners, with current generation batteries designed to retain 80-90% capacity after 200,000+ miles.

The economic impact of these maintenance savings accumulates over vehicle ownership. Studies suggest Tesla owners can save between $5,000-$10,000 in maintenance costs over a five-year period compared to luxury internal combustion vehicles. This reduced maintenance burden also means less time spent at service centers and greater vehicle availability for owners.

However, it’s worth noting that when specialized components do require service, Tesla repairs can be more complex and potentially costly due to the proprietary nature of many components. The specialized training required for Tesla technicians and the current limitations in third-party repair options can impact service availability in some regions.

Manufacturing Advantages of Simplified Mechanics

Tesla’s revolutionary approach to vehicle design, with significantly fewer moving parts than traditional combustion vehicles, creates substantial manufacturing advantages that ripple throughout their production process.

The dramatic reduction in moving parts—from thousands in conventional cars to just 20-25 in Tesla’s electric powertrain—fundamentally transforms how these vehicles are assembled. With fewer components to manufacture, install, and calibrate, Tesla achieves remarkable production efficiencies. Assembly lines can be streamlined, with fewer specialized stations and less complex procedures. This simplification allows Tesla to achieve higher production volumes with less factory space and fewer assembly steps.

Assembly time benefits enormously from this mechanical minimalism. While a traditional combustion engine might require hours to assemble with its hundreds of precisely fitted components, Tesla’s electric motors can be assembled in a fraction of that time. This accelerated assembly contributes to Tesla’s ability to scale production rapidly when needed, as evidenced by their growing manufacturing capacity worldwide.

Quality control also improves substantially with fewer moving parts. Each component represents a potential failure point, so reducing their number mathematically decreases the probability of defects. Tesla’s quality assurance teams can focus their attention more intensively on fewer critical components, ensuring higher overall build quality. The simplified design also makes it easier to trace any issues that do arise back to their source, enabling faster resolution and continuous improvement.

The manufacturing simplicity extends to Tesla’s supply chain as well. With fewer unique parts to source, the company can cultivate deeper relationships with a smaller number of suppliers, potentially securing better pricing and more consistent quality. This streamlined supply network also reduces logistics complexity and vulnerability to supply disruptions.

How many moving parts are in a Tesla? The answer to this question directly impacts Tesla’s ability to pioneer new manufacturing approaches like their “gigacasting” technique, where entire sections of the vehicle frame are cast as single pieces rather than assembled from dozens of smaller components. This revolutionary production method would be impossible without the fundamental rethinking of automotive design that electric vehicles enable.

Future Innovations: Even Fewer Moving Parts?

Tesla’s engineering philosophy has consistently centered around simplification, and this trend shows no signs of slowing down. The company continues to innovate in ways that could further reduce the already minimal number of moving parts in their vehicles.

One of the most promising developments is Tesla’s structural battery pack, introduced with the Model Y. By making the battery pack a load-bearing element of the chassis, Tesla eliminates numerous connecting components and structural supports. This innovation not only reduces weight and improves efficiency but also eliminates dozens of fasteners and assembly components that would otherwise be necessary.

Tesla’s next-generation motors are also likely to feature even simpler designs. Rumors from Tesla’s engineering teams suggest they’re developing motors with fewer internal components while maintaining or even improving performance metrics. The company’s acquisition of several motor technology startups points toward revolutionary designs that could reduce moving elements by another 15-20%.

The Cybertruck’s exoskeleton design offers a glimpse into Tesla’s future approach—using the vehicle’s skin as a structural element eliminates hundreds of supporting components found in traditional vehicles. This unibody-plus approach could eventually extend to other models in the lineup.

Perhaps most intriguing is Tesla’s research into solid-state batteries, which would eliminate the need for cooling systems currently required for lithium-ion batteries. These next-generation power sources would have no internal moving parts and require significantly less thermal management, potentially eliminating pumps, valves, and other components from Tesla’s already streamlined design.

Tesla is also exploring more integrated electronics systems that combine multiple control units into single processors, reducing the need for separate cooling systems and mechanical connections between components. The company’s vertical integration allows them to design custom silicon and control systems that eliminate redundancies found in vehicles using off-the-shelf parts.

As Tesla pushes toward fully autonomous vehicles, we may eventually see the elimination of steering columns, brake pedals, and other driver control mechanisms—components that contain dozens of moving parts in current vehicles. While regulatory requirements will determine the timeline for such changes, Tesla’s prototypes are already exploring these possibilities.

FAQs About Tesla’s Moving Parts

How does the number of moving parts in a Tesla compare to a traditional gas car?

A Tesla electric vehicle contains approximately 20-25 moving parts in its drivetrain, while a conventional internal combustion engine vehicle has over 200 moving parts in the drivetrain alone. When you consider the entire vehicle, traditional cars contain thousands of moving components including pistons, valves, crankshafts, camshafts, timing belts, fuel injectors, and complex transmission systems with hundreds of gears and clutches. Tesla’s electric motor has just one primary moving component—the rotor—which spins within a stationary stator. This represents roughly a 90% reduction in powertrain moving parts, fundamentally transforming vehicle reliability, maintenance requirements, and manufacturing complexity.

Do all Tesla models have the same number of moving parts?

The number of moving parts varies slightly between Tesla models, but the differences are minimal compared to the massive gap between any Tesla and conventional vehicles. Models with dual-motor or tri-motor configurations have additional motors, which adds one primary moving component per motor. The Model S and Model X with air suspension have a few more moving parts in their suspension systems compared to the standard suspension in Model 3 and Model Y. However, even the most complex Tesla configuration still contains dramatically fewer moving parts than the simplest conventional vehicle. The core principle of mechanical minimalism applies across Tesla’s entire vehicle lineup.

What maintenance do I need to perform on a Tesla with so few moving parts?

Tesla’s reduced mechanical complexity translates to remarkably minimal maintenance requirements. You’ll never need oil changes, transmission fluid replacements, timing belt services, or spark plug replacements. Tesla’s official maintenance schedule includes cabin air filter replacement every 2-3 years, brake fluid testing every 2 years, air conditioning service every 4-6 years, and tire rotation every 10,000-12,000 miles. The regenerative braking system means brake pads can last well beyond 100,000 miles, sometimes even the lifetime of the vehicle. Studies suggest Tesla owners save between $5,000-$10,000 in maintenance costs over five years compared to luxury combustion vehicles, making ownership significantly more economical over time.

How does Tesla’s single-speed transmission work with so few parts?

Tesla’s single-speed transmission contains roughly 20 moving parts compared to the 800-1,000 parts in a traditional automatic transmission. This radical simplification is possible because electric motors deliver consistent torque across a much wider RPM range than internal combustion engines. While gas engines need multiple gears to maintain optimal power delivery at different speeds, Tesla’s electric motor can efficiently operate from zero to maximum speed using just a simple reduction gear that connects the motor to the drive wheels. This eliminates the need for complex planetary gear sets, clutch packs, valve bodies, and torque converters found in conventional transmissions, resulting in less friction, reduced weight, improved reliability, and virtually no maintenance requirements.

Does having fewer moving parts mean Tesla vehicles are more reliable?

The dramatic reduction in moving parts generally contributes to improved reliability, as each component represents a potential failure point. With 90% fewer moving parts in the drivetrain, Tesla eliminates countless opportunities for mechanical wear, breakage, and malfunction. Electric motors are designed to function for over 1,000,000 miles before requiring major service, far exceeding typical internal combustion engine lifespans. The simplified design means less friction, reduced heat generation, and fewer components requiring lubrication. However, it’s important to note that when specialized Tesla components do require service, repairs can be complex and potentially costly due to their proprietary nature and the need for specialized technician training. Overall, the mechanical simplicity translates to enhanced long-term reliability and reduced maintenance frequency.

What moving parts does Tesla’s regenerative braking system eliminate?

Tesla’s regenerative braking system doesn’t completely eliminate traditional brake components, but it dramatically reduces their usage and wear. The system uses the electric motor as a generator during deceleration, converting kinetic energy back into electricity while slowing the vehicle. This means the mechanical friction brakes—which still exist for emergency stopping—experience approximately 50% less wear than in conventional vehicles. Many Tesla owners report brake pads lasting well beyond 100,000 miles, compared to the typical 30,000-50,000 miles in gas-powered cars. The regenerative system primarily uses existing motor and power electronics rather than dedicated mechanical components, reducing the number of moving parts in constant operation and eliminating common brake issues like squeaking, uneven wear, and excessive brake dust accumulation.

How many moving parts are in Tesla’s battery system?

Tesla’s battery system operates with astonishing mechanical simplicity, containing virtually zero moving parts during normal operation. The battery pack consists of thousands of individual lithium-ion cells that remain stationary within modules secured beneath the vehicle’s floor. Unlike traditional fuel systems with pumps, injectors, and valves totaling 20-30 moving parts, Tesla’s battery accomplishes energy storage and delivery through electrochemical processes at the microscopic level. The only true moving components are in the thermal management system, which uses a liquid coolant pump and possibly a few valves to maintain optimal battery temperatures—adding just 2-3 moving parts total. This represents another area where Tesla has replaced dozens of mechanical components with solid-state electronics and elegant engineering solutions.

Will future Tesla models have even fewer moving parts?

Tesla continues to innovate toward even greater mechanical simplification. The company’s structural battery pack design, introduced with newer Model Y vehicles, eliminates numerous connecting components by making the battery a load-bearing chassis element. Next-generation motors currently in development may feature 15-20% fewer internal components while improving performance. The Cybertruck’s exoskeleton design uses the vehicle’s skin as a structural element, eliminating hundreds of supporting components. Research into solid-state batteries could eliminate cooling system pumps and valves entirely. As Tesla moves toward fully autonomous vehicles, traditional driver controls like steering columns and brake pedals—which contain dozens of moving parts—may eventually be eliminated. The company’s vertical integration and custom silicon development enable continuous reduction of redundant components and mechanical complexity.